In operational technology (OT) environments—think industrial control systems, SCADA networks, and manufacturing floors—asset visibility is the foundation of security and reliability. Yet most organizations still rely on fragmented spreadsheets or basic network scans that spit out raw data: an IP address here, a device type there, a firmware version somewhere else. These isolated details are like puzzle pieces scattered on the floor.

Without context, they’re useless. Enter the contextualized OT asset inventory: a dynamic, interconnected view that transforms those isolated fragments into actionable knowledge. Let’s explore how this works and why it matters.

The Problem with Isolated OT Asset Data

Imagine discovering a device at 192.168.10.45 running Windows 7. That’s useful… until you realize:

– You don’t know what it does (engineering station? SCADA? Office pc for email?).

– You don’t know its communication patterns (does it talk to the internet?).

– You don’t know its vulnerabilities in context (can apps be updated without shutting down production?).

– You don’t know its risk score relative to business impact.

Isolated data creates blind spots. Security teams see a vulnerability but can’t prioritize it. Operations teams see a device but can’t assess downtime risk. Compliance teams see an IP but can’t prove audit readiness. Maintenance has a grip on the device but doesn’t know it’s firmare is outdated, and the model is end-of-life.

What Is a Contextualized OT Asset Inventory?

A contextualized inventory goes beyond static lists. It enriches every asset with layered intelligence:

| Raw Data | + Context | = Actionable Knowledge |

| IP: 10.0.0.112 | → Connected to Valve #3 in Machine Line 2 | → Critical path asset |

| Device: Siemens S7-1200 | → Firmware v3.0.1 (CVE-2022-1234) | → High-risk, update during next maintenance window |

| MAC: 00:1A:2B:3C:4D:5E | → Communicates with ERP system nightly | → Potential lateral movement vector |

This isn’t just metadata—it’s operational intelligence.

How Context Turns Data into Decisions

1. Risk Prioritization No Longer Is Guesswork

Instead of triaging 500 CVEs by CVSS score alone, context reveals:

– Business impact: Does this PLC control a $2M/hour production line?

– Blast radius: If compromised, how many downstream systems are affected?

– Exploitability: Is it exposed to the IT network or internet-facing?

Action: Patch this device first, even if its CVSS is 7.0, because downtime costs > $500K.

2. Incident Response Becomes Surgical

An alert fires: “Unauthorized traffic from 172.16.0.88”.

With context:

– It’s a legacy HMI in the paint shop.

– It only talks to one PLC (whitelisted).

– It’s air-gapped except for USB updates.

Action: Quarantine the HMI, audit USB policies—not the entire subnet.

3. Compliance Becomes Proactive

Regulators want proof of asset management (NERC CIP, IEC 62443, NIST 800-82). Top management wants proof that OT networks are aligned with corporate policy.

A Contextualized OT asset inventory delivers:

– Change logs with business justification.

– Segregation proof (VLAN + firewall rules + asset role).

– Patch status tied to maintenance schedules.

– Proof of the absence of prohibited software apps (TeamViewer, Adobe Flash etc.)

– Proof of the absence of insecure protocol usage (think Telnet, HTTP).

Action: Generate audit-ready reports in 5 minutes, not 5 days.

Building a Contextualized Inventory: Key Layers

To move from IPs to intelligence, enrich assets with these dimensions:

| Layer | Example | Why it matters |

| Physical | Rack 4, Area 2, Line B | Unambiguous device identification |

| Functional | Controls Boiler #2 feed pump | Links to process criticality |

| Network | VLAN 30, talks to DCS historian | Reveals segmentation gaps |

| Threat | CVE/KEV + exposure | Drives risk scoring |

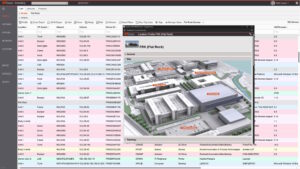

The OTbase OT Asset Management software provides all the necessary data dimensions and workflow automation. Data enrichment for key areas such as CVE, network connectivity, vendor safety advisories, and product obsolescence is performed automatically.

The Bottom Line

An IP address is just a number.

A contextualized asset is a story: “This device controls a $10M process, hasn’t been patched in 18 months, and talks to a server in layer 4.”

That’s not data—that’s actionable knowledge.

In OT, where cyber meets physical, context isn’t optional. It’s the difference between reacting to incidents and preventing them. Between compliance checkboxes and defensible architecture. Between managing assets and mastering risk.

Stop collecting IPs. Start building asset knowledge. Check out the OTbase OT Asset Management software. It helps some of the largest manufacturing enterprises to build resilient OT infrastructures at scale. To learn more about OTbase, check out https://otbase.com.